By RENA

Supplier InfoProduct Type:

Equipment

Application:

Wet Processing

Product Description:

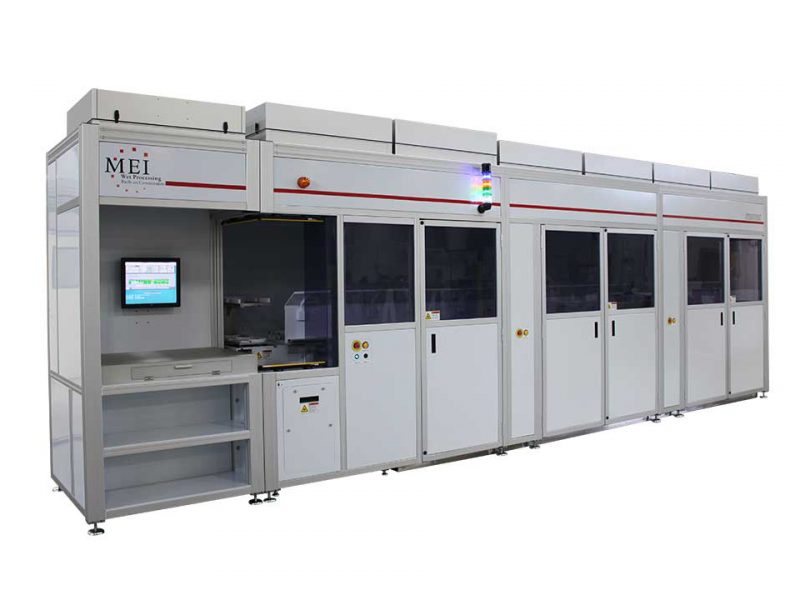

MEI’s Revolution is an automated, multi-step, Rotary wet bench system. With IDX Flexware Control, an integrated rotary robot, and a custom process tank configuration MEI creates powerful, flexible solutions and equipment that require minimal footprint. SECS/GEM compliant IDX Flexware Process Control software provides outstanding control and flexibility, custom-tailored to your process solution. Our new, robust rotary robots can handle carriers up to 300 mm wafers through multiple process steps and recipe configurations. Configurability, up-time, yield, maintainability, and throughput are the hallmarks of an MEI wet processing system.

Features for Optimum Performance

- 2–5 tanks

- Megasonic or ultrasonic bath

- Heater (including solid-state), chiller, and dryer options

- Chemical spiking, in-tank blending, filtration concentration monitoring, bulk fill, agitation, DI flush, and drain options

- PVDF, stainless, quartz, Halar, or natural poly

- Optional tank lids

- Pressure or optical tank level monitoring

- QDR tank with sparger bar spraying method, shared facilities,

- Robust dump cylinder

System Options

- Custom Designed for Your Process

- 100–300 mm wafer Sizes

- Input/output queues or manual loading

- Acid/base or solvent

- Choice of FM4910 (Halar, CPVC, PVDF), polypropylene, or stainless steel

- Chemical spiking, recirculation, and filtration

- Manual pour chemistry via deck-mounted cup or chemical spiking reservoir

- End effector materials PVDF/ PTFE, Halar, quartz, or stainless steel

- Fire suppression (available upon request)

Integrated Dryer Options

- Technology node 200 nm

- Best particle performance on hydrophilic surfaces

- Compatible with processing

- Teflon cassettes

- Slow-drain Marangoni process

- Static wafer lifter to minimize water contact marks

- Dry cycle time 15–20 min

- 10–20 ml IPA per cycle

- Etch, Strip, Cleaning, and MLO Wet Bench with Minimal Fab Footprint FEOL Resist Strip

- RCA Clean

- BEOL Resist Strip

- InGaP-GaAs Etch

- Post CMP Clean

- Prediffusion Clean

- Oxide Etch

- SWP Clean

- Developer

- Nitride Etch