By AXUS

Supplier InfoProduct Type:

Equipment

Application:

CMP Remanufactured

Product Description:

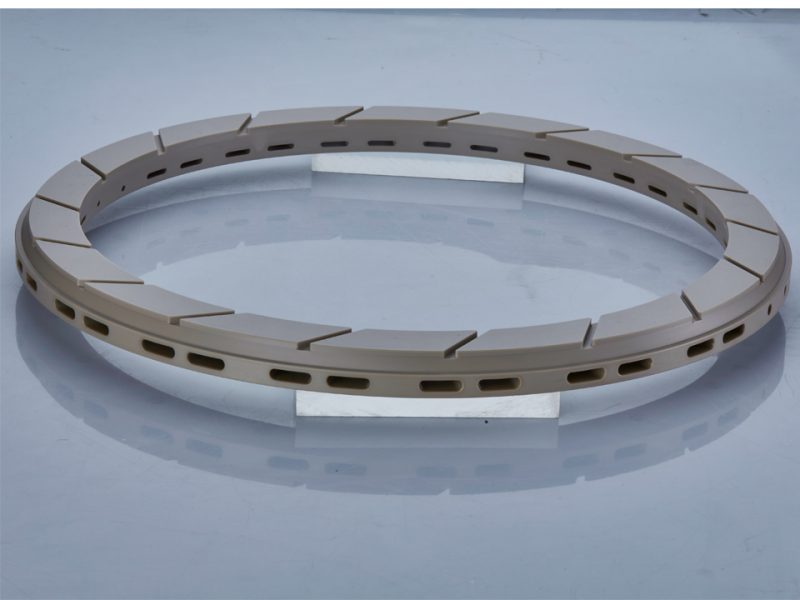

AXUS technology specializes in the remanufacturing of CMP, Wafer Grinding & Wafer Cleaning Equipments as well as the supply of upgrades and spare parts. The Surface / IPEC 472 wafer polisher is a fully automated, precision tool for CMP polishing of semiconductor wafers used to achieve flatness, uniformity, and planarization on patterned/device wafers. The Surface / IPEC 472 features automatic wafer handling and is capable of two-platen, two-step polishing processing to maximize wafer throughput capability and quality. Designed to planarize wafers from 100 mm to 200 mm, the Surface / IPEC 472 is ideally suited for materials polishing applications that require repeatability with operational and processing flexibility. Only Axus Technology is authorized to provide ViPRR carrier upgrades for refurbished IPEC 372M and Surface / IPEC 472 CMP tools. The Surface / IPEC 472 supports many conditioner and carrier upgrades.

- Fully automated precision polishing

- Two platen processes for post-polish buff

- Multiple slurry dispense

- In-situ pad conditioner

- Material compatibility for medium and low pH slurries (1-12)

- Downforce up to 750 lbs.

- Controllable wafer back pressure

- Polish head clean station

- External interface for end-point capability

- Temperature controlled platens

- Multizone ViPRR carrier upgrade

- SECS II Interface

Production-proven for oxide, shallow trench isolation (STI), polysilicon, tungsten, and copper planarization applications