By IMT

Supplier InfoProduct Type:

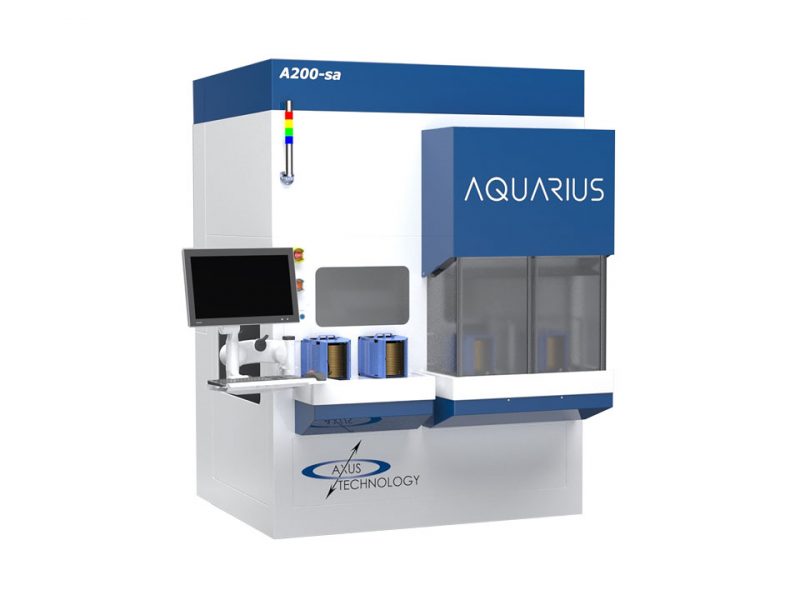

Equipment

Application:

Dry Processing & UHP

Product Description:

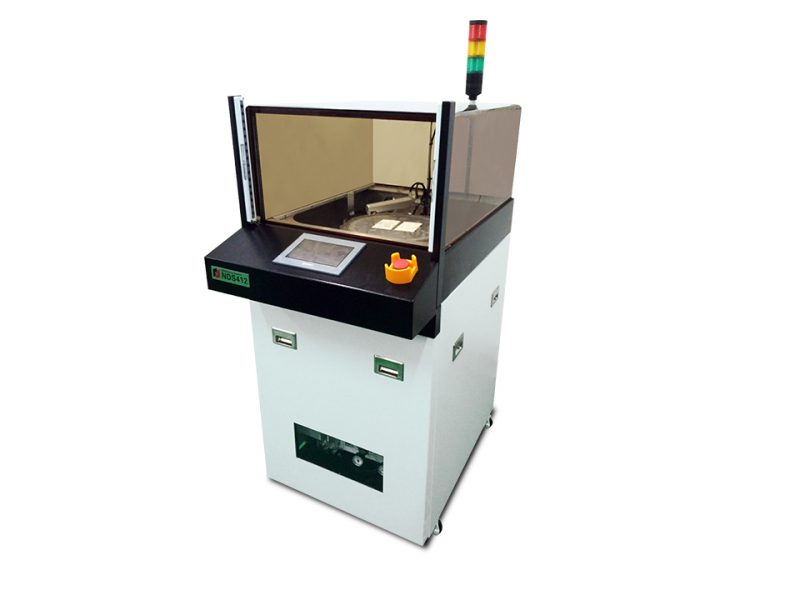

The DANDI 3100 Wafer Cleaning System from IMT is an advanced solution specifically designed for high-performance cleaning of HBM (High Bandwidth Memory), 3D stack or MEMS wafers. It effectively removes for example fine particles generated during the DRAM wafer dicing process, ensuring clean surfaces that are critical for the memory stacking process.

Key Features:

-

Fine Particle Removal:

The DANDI 3100 excels at removing even the smallest particles formed during the wafer cutting process, helping to reduce contamination and improve wafer quality.

-

Improved Defect Rate:

By optimizing the cleaning process, the system significantly reduces defects for example during the memory stacking process, leading to better overall performance and reliability.

-

High-Speed, Simple Process:

The DANDI 3100 offers a streamlined dry cleaning process with a fast throughput of over 40 wafers per hour (wph), making it highly efficient for large-scale production.

-

User-Friendly Interface:

Its intuitive design allows for easy integration into existing production lines, requiring minimal operator intervention.

The DANDI 3100 Wafer Cleaning System is the ideal solution for semiconductor manufacturers looking to improve the quality and efficiency of their production processes.

CO₂ Cleaning Technology

CO₂ Cleaning Mechanism

- Physical Blasting

Dry ice particles are accelerated by compressed air and collide to the surface - Thermal shock

Sublimation heat of -78.5℃ shrinks foreign matters and causes cracks - Sublimation expansion

Expands volume to 800 times and breaks the boundary - Ablation

Uses the air pressure of the high-speed compressed air to remove

Dry-ice (Size: variable) + CDA (Clean Dry Air)

Advantages of the CO2 Cleaning

- Free from chemicals/water

- No need for an additional drying process

- Minimum secondary waste after cleaning

- Free from surface damages

- Easy automation

Applications in Semiconductor/MEMS:

- TSV

- MEMS Wafer Particle Removal

- Bare Wafer Epoxy

- PR residues Cleaning or Organics Contaminations and residues Cleaning

- Bump Wafers and Removal of Bond Residues

- Glass Carrier Cleaning

- Wafer Backside Cleaning

- EdgeContaminations Cleaning

- Framed Wafers Cleaning after Dicing