By IV Technologies

Supplier InfoProduct Type:

Parts & Consumables

Application:

CMP Consumables

Product Description:

IV Technologies has been concentrating on developing CMP consumables for over 20 years. They offer CMP Hard pad, Soft pad, Membrane and Parts with more than 100 global issued and pending patents.

PU Polyurethan Pad for Multiple Applications:

Advantages

HV series: High RR / Long lifetime / Low defectivity

GV series: High PE / Reliability / Low defectivity

| Application | Offering | Benefit |

| STI / OX | HV2000 / HV6000 / HV8000 | Industry Standard, High RR / Low Defectivity / Long L/T |

| GV2000 / GV3000 | Stable RR / High PE > HV series |

Core Technology

Our pad utilizes proprietary polyurethane formulation & synthetic technology, molding Process, polymer elastomer, CNC machine tool precision processing, and laminating technology.

PU/Elastomer Technology

Material Formulation

iVT pad/membrane is made from exclusive PU/elastomer formulation & synthetic technology. Molecular configuration can be optimized to various polishing requirements.

Innovative Processing

iVT pad provides better PtP quality control with single pad manufacturing. Real-time QC items can ensure the quality & stability of the pad/membrane.

Structure & Performance

The physical properties of the iVT pad can be controlled & adjusted in a specific range. General pore size is uniform & pore structure can be arbitrarily made to close/open pore.

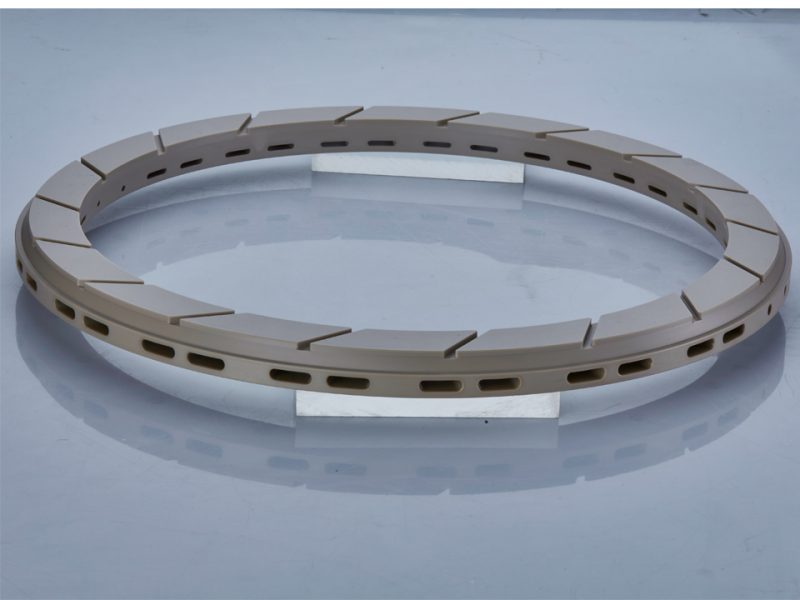

CNC for Various Grooving Designs

Groove Design

The grooving pattern of iVT pads is presented by exclusive design, which is reliable for IP concerns, through various CNC skills. Complex and novel grooving types like C-groove and radial spiral can be accomplished, and the grooving details can also be customized.

Dimensional stability

The CNC tools applied on the iVT pad have precise dimensions. All tools are examined by QC items regularly. Therefore, the relative grooving dimension of the pad can offer steady performance in CMP serving.

Customization

iVT CMP pad design is highly customizable to meet different customer’s technology challenges and needs.

There are currently no specifications available.

There are currently no videos available.

Currently, no information for the application is available.