By MEI / RENA

Supplier InfoProduct Type:

Equipment

Application:

Integrated IPA Drying

Product Description:

RENA’s Genesis Marangoni Dryer integrates drying with cleaning and rinsing, providing a one-step process for applications including the fabrication and cleaning of ICs, solar cells, fuel cells, and MEMS. The entire process is monitored and controlled by RENA’s proprietary IDX Process Control software.

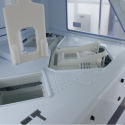

Processing

- Enables Dry In – Dry Out Processing

- Simplified Marangoni dryer design

- Teflon cassettes @ > 200nm w/5mm EE

- Static wafer lifter

- Hydrophobic or Philic surfaces

- Particle performance

- Uses Teflon cassettes

- Ideal for drying thin wafers

- Typical 7-20 min cycle time

- Will not damage photoresist

Intuitive Integration

- Active lifter for independent wafer

- Low mass carrier drying @ 30nm w/3mm EE

- Slow pull wafer lifter

- Wafers dried independently of the carrier

- Phobic or Philic surfaces

- Particle performance

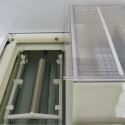

- Uses low mass wafer carrier

- Optional IPA recirculation & filtration to 15nm

- Typical 10 min cycle time

- Will not damage photoresist

- Produces oxide free H terminated surface with no air interface

- HF injection is best used for complete oxide strip applications

- Combination HF, HCl, and DIO3 rinse provides high-quality surfaces

- Cycle times are application dependent

- O3, HF or HCl Injection for Critical Clean Applications

RENA Genesis Marangoni Dryer Features:

- Robust

- Efficient

- Clean

- Cost Effective

- Recirculating for reduced IPA usage

- Low cost of ownership

file_downloadIntegrated_Dryers.pdf

There are currently no videos available.

Theres currently no information available for application.