By MEI / RENA

Supplier InfoYou might be interested in:

Electroplating EPM 2

Advanced manual electrochemical deposition Highest flexibility is required for pure metal and alloy deposition in the Microelectronic,…

Product Type:

Equipment

Application:

Wet Process

Product Description:

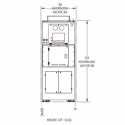

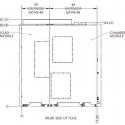

Inception – Single wafer processing tool

RENA Inception, the compact semi-automated single wafer processing system is an ideal solution for wet chemical cleaning, etching and resist tripping processes. This platform enables transition from R&D to pilot production in semiconductor manufacturing. Inception can be applied for acid applications in FEoL as well as solvent applications in BEoL. It provides superior etch uniformity <= 1% within wafer, from wafer to wafer and from lot to lot.

Inception consists of Dual moving spray arms with separate chemical lines which together with multiple tank design provides multi-step processing features. A variation of chucks are available for different wafer and substrate sizes to allow easy setup for different applications.

RENA’s IDX Flexware softwareprovides many advantageous features for process control and monitoring. All RENA systems are compliant to the SECS/GEM interface of factory host.

Features and Benefits

- Wafers up to 200mm and masks up to 7 x 7

- Etch uniformity exceeds batch systems

- Manual or automated wafer handling

- Single or dual load port

- 2 to 4 chemical process tank

- Hyper accurate concentration controls (ABB, Horiba, CI Semi)

- Hyper accurate spiking capability (Chemical & DI)

- Automatic chemical compensation for losses

- Small footprint

There are currently no videos available.

- III V and II VI Materials

- HBT

- BiFET

- Mesa Etch