By DYNATEX

Supplier InfoProduct Type:

Equipment

Application:

Bonding

Product Description:

The DXB 880 features an onboard process controller that automates the entire wafer bonding process. Key features include one-button operation and active cooling.

The automation introduced in the DXB 880 ensures a repeatable, robust process. The user is able to program each process node individually and with extreme precision, while new Active Cooling technology significantly reduces bonding cycle time. The system can be programmed with the desired temperature, pressure, and duration for each step in the sequence. The display shows the status of the bonding sequence as it progresses. The program is stored in local memory for easy access and simple operation, and can be password protected to prevent accidental changes.

- The DXB 880 Automatic Wafer Bonder is used for creating void free wafer bonds.

- Low total thickness variation (TTV) in bond line thickness.

- Onboard process controller automates the entire wafer bonding process.

- The DXB 880 has one button operation for a fully automated process.

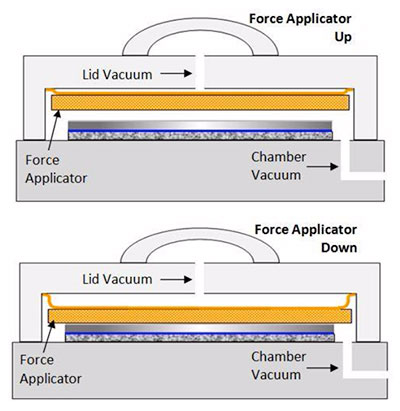

- Dual chamber technology provides precise control of the bonding pressure.

- Active cooling feature allows the bond to set with the bonding pressure on, and provides a fast cycle time rather than the much longer time required for the bonder to cool on its own.

- Heated vacuum chamber 11.25″ diameter.

- Available in two operating voltages – 120 VAC and 240 VAC both single phase.

For more controlled bonding processes, the dual chamber feature provides the best in control, precision and flexibility. The bonding pressure is controlled with extreme precision by adjusting the differential pressure in the two chambers. This allows the wafer to come up to temperature without trapping air in the bondline.

Once the wafer is at temperature the force applicator can be lowered by reducing the vacuum in the lid. The differential between the two pressures provides the bonding pressure to the wafer.

| DXB 880 Series | DXB-880-01 | DXB-880-02 |

| Bonding Chamber Size | 11″ (279 mm) Diameter | 11″ (279 mm) Diameter |

| Temperature Range | 100 – 356° F (40 – 180° C) | 100 – 356° F (40 – 180° C) |

| Cycle Time Range | 1 min – 10 hrs | 1 min – 10 hrs |

| Power Required | 100/120 VAC 10 amps, 50/60 Hz | 220/240 VAC 5 amps, 50/60 Hz |

| Vacuum Required | 18 – 25 inHg | 18 – 25 inHg |

| Coolant | Water (12 liters per minute, 40 PSI) | Water (12 liters per minute, 40 PSI) |

| Environmental | 60 – 80° F (15 – 27° C); 0 – 95% Humidity (non-condensing) |

60 – 80° F (15 – 27° C); 0 – 95% Humidity (non-condensing) |

| Dimensions | Height: 26″ (200 mm); Width: 14.7″ (375 mm); Depth: 21.2″ (440 mm); Chuck: 11.25″ (285 mm) |

Height: 26″ (200 mm); Width: 14.7″ (375 mm); Depth: 21.2″ (440 mm); Chuck: 11.25″ (285 mm) |

There are currently no videos available.

- Wafer Thinning

- Wafer Lapping

- Metal Plating

- Wafer Polishing

- Wafer Dicing

- Deep Reaction Ion Etch

- Any other temporary wafer bonding process